1.Application

Choke manifold is necessary device to control the well kick successfully and execute the pressure control technology on oil/gas well in the course of drilling, as it is, the device is adopted to execute new drilling-well's technique of balance pressure, which can avoid pollution of oil-layer, improve the speed of drilling and control blowout effectively. One end of the device connects with the side flange of BOP spool. When BOP closes, it can control the finite pressure from casing by adjusting the choke valve's opening, so balanced drilling can work under minimum pressure-difference .

2¡¢Assembly &structure

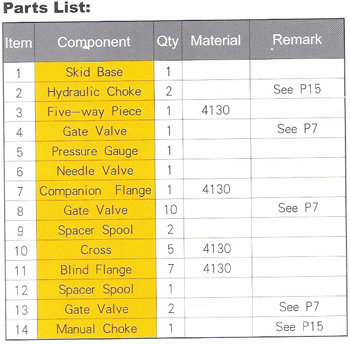

Choke manifold consists of choke valve, gate valve, pipeline, ffittings and pressure gauge etc, see gate valve part and choke valve part in the above drawing.

3¡¢Working principle

When the pressure rising in well,fluid in well can be released in utilization of the choke valve opening/closeing in choke manifold to control casing pressure, which can directly blow out through gate valve as the casing pressure is quite high.

4¡¢Specification

Pressure level is divided into five levels, i.e. 14MPa,21MPa, 35MPa, 70MPa and 105MPa, it can be also designed according to the requirement of customer.

5¡¢0peration requirement

(1)All the working pressures of parts in choke manifold should be matched with the working pressure of BOP stack used;

(2)Choke manifold should be installed at the place where operator approach it conveniently, pressure test should be executed as installation , while the sealing test pressure should be equal to the rated working pressure;

(3)Pipeline should be so smooth and straight as possible, the corner of the pipeline should be made of 120o haped forged steel bent pipe, which should have adequately large bore;

(4)The working pressure gauge should be installed;

(5)In winter, the choke manifold be able to work under a low temp condition.

|